- Knife shop

- Dealer Locator

- Press

-

Service

- < Service

- Dedication

- Brand environment

- Cut & sharpen like a pro

- Knife Academy

- Knife making - Swiss manufacturer

- Knife grinding

- Grinding Service Locator

- Engraving/Gift box

- Newsletter

- News

- About world-of-knives

Cutler - Handicraft of sword forging

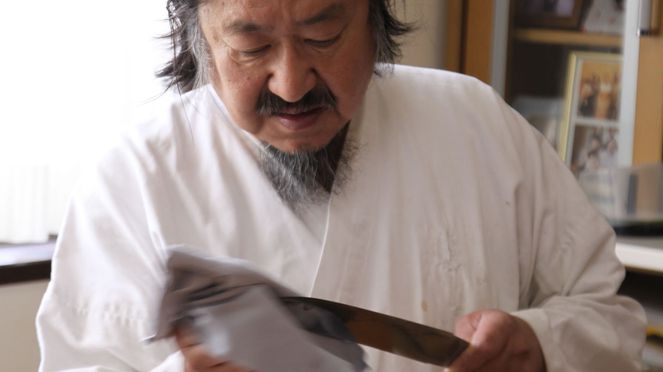

The handicraft of damascene knives fabricated by hand by a cutler is based on the traditionnal art of sword forging. One of the masters of this sword forging is Fujiwara Kanefusa, who fabricates in 25th generation swords for royal houses as for example the King of Jordan or the reigning family of Saudi Arabia. The Kai damask knives made of 32-layer stainless damask steel with their excellent cutting properties and good corrosion resistance are an innovative further development of these damascus knives made according to traditional Japanese samurai sword forging techniques.

Learning the art of sword forging takes 5 years, other 5 years are needed to take the exam of the ministry, which also stipulates the raw material to use.Thanks to the classic melting process from sand, a high level of purity can be reached. The steel is forged according to a special folding techniques with 32'000 layers. Thanks to this folding techniques, the grains are very small. Latest investigastions have shown that the structure of a Samurai sword is in the order of modern nano material. The fineness and the quantity of layers lead to good strength. Then the inner part is forged together with the outer, hard part so that a constant aliance is formed. Up to 20 days of work are needed to produce such a blank of a sword. Working by hand, the cutlers work in the dark, so that they can easier check the temperature. The unique structure - every cutler has his own pattern - appears by applying earth and by hardening. The cutler pre-sharpens the sword to check the quality, then he hands it over to a grinder. After, the sword is passed on for the fabrication of the handle and the sheath, which is decorated by the ornaments of the cutler.